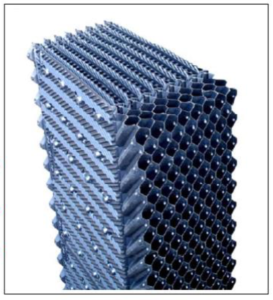

Opti-Pac 7500 ID bundle fill modules meet requirements of the Cooling Tower Institute’s standard for rigid PVC, STD-136.

The function of cooling tower fill is to put as much water in contact with as much air as possible, for the longest amount of time possible within the tower. Film fills allow the water to form thin flowing sheets and expose the water surface area to the interacting flow. Using a block fill guarantees uniformity of sheet spacing which allows the maximum amount of water and air to pass through it.

Once installed, this system forms a long-term, trouble-free replacement for the OEM material, and since it is bottom supported, Opti-Pac 7500 allows for the basin to be easily cleaned out and maintained with a 5-1/2” clearance between the fill and cold-water basin.

Benefits of the Opti-Pac 7500

Available with an integrated louver and with an integrated drift eliminator, Opti-Pac 7500 film fill media are designed to replace OEM hanging fill sheets in crossflow cooling tower applications and will meet or exceed designed tower performance.

- Fabricated from rigid, thermoformed PVC sheets that are solvent-welded for maximum strength

- Resistant to UV, rot, fungus, organic/inorganic solvents, acids, alkalis, and chemicals normally found in cooling tower waters

- Meets the requirements of the Cooling Tower Institute (CTI) standard STD-136

The OP7500 fill has the same specific surface area as the MX75, so efficiency would be identical (51.2 ft2/ft3). Replacing the fill with bottom-supported structural fill blocks, the possibility of sheet stretching or fluttering is eliminated as the product rigidly adheres to solid blocks. In most cases, since the fill is designed for structural considerations, these fill sheets are also much thicker than hanging sheets – anywhere from 20-85% – providing added longevity and UV resistance. Once the fill is installed properly, it is a uniform and rigid block that eliminates the chances of stretching or fluttering.

Shop our parts here.

Click here for more in-depth information on cooling towers and fill media.

Read more about cooling tower fill here.

We’re a phone call or email away!

Count on Commercial HVAC Parts for all your supply needs.

3801 Cherry St

Houston, TX 77026

713-782-2734

parts@commercialhvacparts.com

Monday – Friday

8:00 am to 5:00 pm

Got Cooling Tower Fill?

A Quick Overview of Cooling Tower Fill

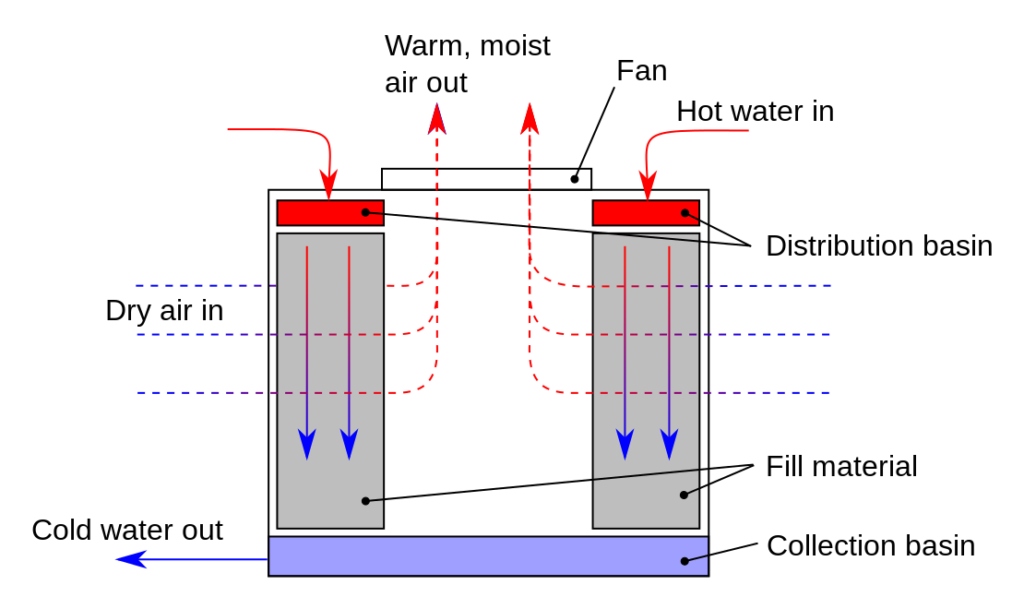

“Fill” is used in cooling towers to allow as much surface area for water as possible. Cooling tower fill is important because it puts water in contact with air for the longest amount of time possible. It allows the tower to completely use the water and spread it across more surface area.

The performance of the fill media function allows for:

- Quicker cooling time

- Longer residency

- Even distribution of water within the tower

What is important when looking for cooling tower fill?

Quality fill is crucial in the efficiency and effectiveness of the tower. It is important to look at the basin clearance, strength/rigidity, spacing of eliminators, and the ease of removal. We are spotlighting Opti-Pac 7500 film fill media, as this product is designed to replace OEM hanging fill sheets in crossflow cooling tower applications.

This particular fill meets or exceeds the designed tower performance. The media is fabricated from rigid, thermoformed PVC sheets that are solvent-welded for maximum strength and resistant to UV, rot, fungus, organic/inorganic solvents, acids, alkalis, and chemicals normally found in cooling tower waters.

The graphic below is a helpful introduction to fill, and we look forward to sharing more details about this media in a separate blog. In the meantime, click here for more in-depth info regarding cooling towers and fill.

We’re a phone call or email away!

At Commercial HVAC Parts, we offer film fill media for your BAC or Marley towers along with a variety of other parts for your HVAC system. Stay tuned for more posts regarding specific fill types, the specifications of the material, and information on the other products we carry.

As always, feel free to contact us online or speak with an expert regarding fill options at 713-782-2734.

Count on Commercial HVAC Parts for all your supply needs.

3801 Cherry St

Houston, TX 77026

713-782-2734

parts@commercialhvacparts.com

Monday – Friday

8:00 am to 5:00 pm

Product Spotlight: BAC Bearings

BAC Bearings — BALTIMORE AIRCOIL COMPANY

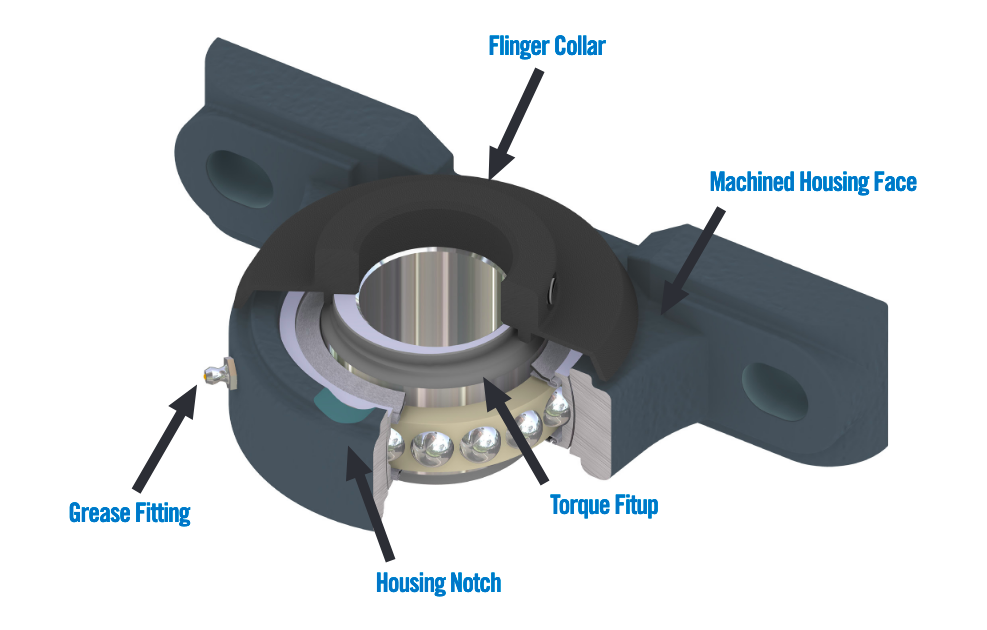

We proudly carry BAC bearings, which are longer lasting with rugged, cooling tower duty construction. This results in less maintenance downtime, water ingress prevention, and corrosion resistance.

Customized BAC bearings offer you peace of mind when it comes to your cooling tower

BAC bearings

BAC bearings offer you peace of mind when it comes to your cooling tower. The right bearing execution is critical for your application to benefit from the maximum lifetime. Specifically, bearings that operate inside cooling towers are exposed to tough conditions, operating within a moist and hot environment. BAC offers specially engineered and tested bearings to meet rigorous standards.

What’s in it for you?

- Longer bearing L10 life of 80,000 hours compared to 20-40,000 hours for other manufacturers’ bearings

- Less overall maintenance downtime for the life of the unit, reducing production losses and overall labor costs

- Durable construction and innovative design increase bearing life expectancy and decreases unit downtime for corrective maintenance and frequent replacement

- Grease fitting location is unique, by injecting grease into the top of the bearing and using gravity to push old, contaminated grease out of the bottom

- BAC’s design prevents water ingress, one of the largest reasons for bearing failure

- Corrosion is prevented by utilizing unique BAC construction features such as the housing notch and flinger collar

- Unique specification for operation in harsh conditions, within a moist and hot environment.

- Ensures the continuous, reliable operation of the cooling tower, avoiding loss of production through downtime

- Avoids frequent replacement or service works, which come at a high cost

- Ensures that your fan shaft, propeller, and other drive elements are not at risk of premature failure

See more about BAC bearings here.

See all of our BAC products here.

We’re a phone call or email away!

Count on Commercial HVAC Parts for all your supply needs.

3801 Cherry St

Houston, TX 77026

713-782-2734

parts@commercialhvacparts.com

Monday – Friday

8:00 am to 5:00 pm