How Do Cooling Towers Work?

Cooling towers utilize evaporative cooling to adjust the temperature of whatever environment they are supposed to. Evaporative cooling occurs everywhere – it is the simple process of water evaporating into the air. A perfect example of evaporative cooling in everyday life would be sweating. When an individual is hot, they sweat. The sweat then evaporates off the skin, pulling heat out of the body and creating a cooling effect. Stepping out of a pool also demonstrates this – you feel significantly cooler while air drying getting out of the water.

Cooling towers are large structures designed with the purpose of maximizing the evaporative cooling process. In the tower, water is first passed through a heat exchanger where it absorbs heat. The water is then distributed over the top of the cooling tower where air travels past the warm water causing a portion of the water to evaporate. Cooling towers typically contain “fill,” a material consisting of PVC plastic sheets, to create more surface area for the evaporation of water to occur. The heat is transferred from the water stream to the air stream, raising the air’s temperature and its relative humidity to 100%. This warm air is then discharged into the atmosphere, resulting in a cool water stream. The cooled water from the basin is then pumped back through a heat exchanger and the cycle repeats. For more information on cooling tower fundamentals, click here.

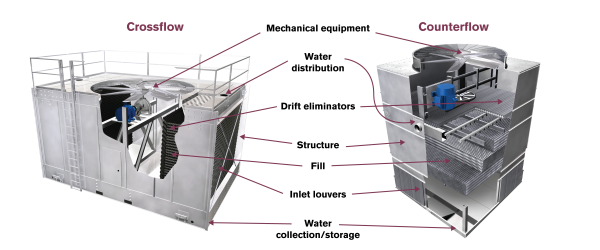

Types of Cooling Towers

We’re a phone call or email away!

Count on Commercial HVAC Parts for all your heating and cooling supply needs.

3801 Cherry St

Houston, TX 77026

713-782-2734

parts@commercialhvacparts.com

Monday – Friday

8:00 am to 5:00 pm